News

Nolifriit Successfully Solves Bubble Holes Defect for Enamel Hob By High-Quality Enamel Powder

- Categories:Company news

- Author:

- Origin:

- Time of issue:2022-07-22

- Views:0

(Summary description)If there are bubbles and pores in enamel products, it will have a great impact on the appearance and quality of the products. Recently, a customer from South America

Nolifriit Successfully Solves Bubble Holes Defect for Enamel Hob By High-Quality Enamel Powder

(Summary description)If there are bubbles and pores in enamel products, it will have a great impact on the appearance and quality of the products. Recently, a customer from South America

- Categories:Company news

- Author:

- Origin:

- Time of issue:2022-07-22

- Views:0

If there are bubbles and pores in enamel products, it will have a great impact on the appearance and quality of the products. Recently, a customer from South America was troubled by the defects of bubble holes in the enamel hob, so he contacted us, and finally, with the technical help of Nolifrit, he found the reason and solved the problem perfectly. .

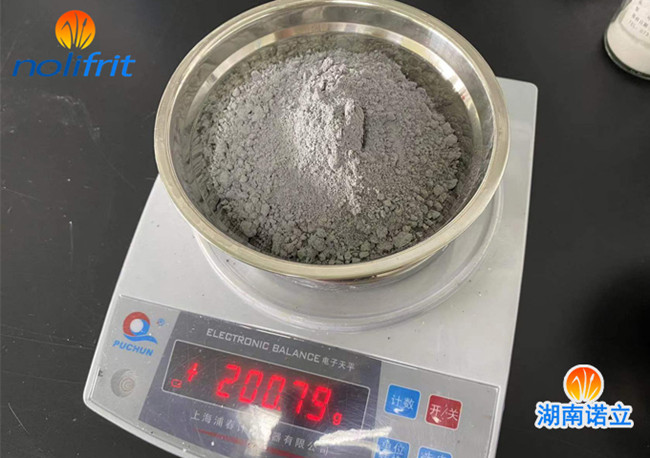

After receiving the customer's consultation, we immediately learned the details of the other party's enamel defects. After investigation and analysis and experimental operation, we found that the quality of the enamel pre-grinding powder used by the customer before was not good, resulting in the finished product after firing. There will be defects in the porcelain surface, which will seriously affect the quality of the product. To this end, Nolifrit offers an alternative: Nolifrit high-quality enamel powder RTU.

In order to allow customers to see the difference between Nolifrit pre-grinding powder and the previous pre-grinding powder more intuitively, Nolifrit technical team provided customers with 2 samples, which were first proofed in the R&D center and pre-grinded with two different thicknesses. The powder is ground with water (because the customer has requirements on the thickness and uniformity, in order to make the product better, grinding is recommended. Ordinary enamel pre-grinding powder does not need to be ground, just add water and stir evenly to coat and use). After proofing, the porcelain surface of the product is smooth and the adhesion is good. It has passed professional testing, meets customer standards, and is affordable. Compared with other international brands, it has a more obvious price advantage, which can effectively save user costs.

Nolifrit always insists on providing professional services and high-quality products to customers around the world. If you have any related needs, please contact us!

Scan the QR code to read on your phone

CONTACT US

Location:No199, North Zhujiang Road Tianyuan District,

Zhuzhou City, Hunan Province, China

Tel:+86-731-28212146 +86-731-28212147

Mobile: +86-13574208778

Email: jack@nolifrit.com

WhatsApp : +8613574208778

WeChat :+8613574208778