News

How To Save Energy In The Enamel Desulfurization Plate Firing Furnace

- Categories:Company news

- Author:

- Origin:

- Time of issue:2022-11-25

- Views:0

(Summary description)

How To Save Energy In The Enamel Desulfurization Plate Firing Furnace

(Summary description)

- Categories:Company news

- Author:

- Origin:

- Time of issue:2022-11-25

- Views:0

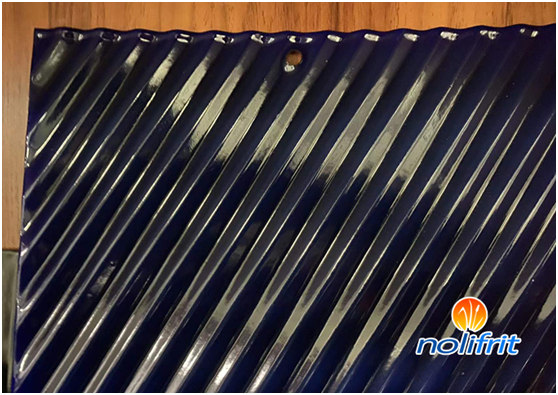

The enamel desulfurization plate is similar to a corrugated flat plate, and its quality and thickness are not large compared with the water heater. In order to increase the loading capacity of the firing furnace, multiple pieces are hung on one hanger for firing, and each hanger generally hangs 4 to 5 pieces. The length of the product is long and the width is small, so the turning radius in the furnace is required to be large, but the small width in the parallel section of the firing chamber is beneficial to energy saving. The hanging pitch determines the turning radius. If the two cannot be approximately equal, the turning radius must be satisfied. At this time, the furnace shape is similar to a scoop shape (or polygon) on the U-shape basis.

The desulfurization board adopts one-time dipping and enamelling. After being glazed, it is directly hung on the firing chain and enters the heat exchange belt for drying. In particularly cold regions, the length of the heat exchange belt can be extended or the electric drying power can be increased. This kind of firing furnace has simple process and high production efficiency. According to the product shape and hourly heating capacity, the current power of the kiln can be as small as 375kW and as large as 1100kW.

Nolifrit is a supplier of enamel glazes and inorganic pigments. If you have any relevant information, please contact us!

Scan the QR code to read on your phone

CONTACT US

Location:No199, North Zhujiang Road Tianyuan District,

Zhuzhou City, Hunan Province, China

Tel:+86-731-28212146 +86-731-28212147

Mobile: +86-13574208778

Email: jack@nolifrit.com

WhatsApp : +8613574208778

WeChat :+8613574208778