News

Defects of Enamel Products: Analysis of The Causes of Bubbles

- Categories:Enamel Defects

- Author:

- Origin:

- Time of issue:2022-01-11

- Views:0

(Summary description)When the enamel frit and the metal body are fired, gas will be generated. The gas that is not completely discharged forms "bubbles"

Defects of Enamel Products: Analysis of The Causes of Bubbles

(Summary description)When the enamel frit and the metal body are fired, gas will be generated. The gas that is not completely discharged forms "bubbles"

- Categories:Enamel Defects

- Author:

- Origin:

- Time of issue:2022-01-11

- Views:0

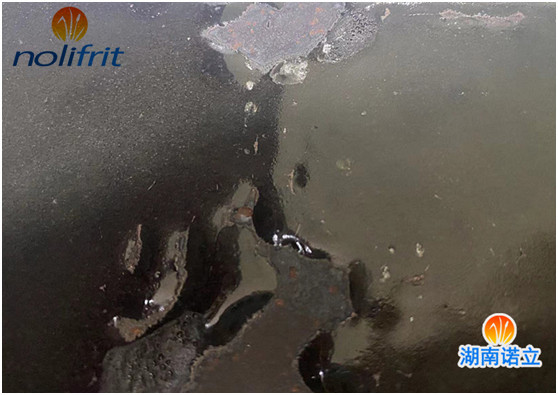

When the enamel frit and the metal body are fired, gas will be generated. The gas that is not completely discharged forms "bubbles" on the surface of the porcelain layer, and "holes" are formed when the surface of the porcelain layer is broken. Cells are generally common in cast iron enamel products, because of the high non-ferrous composition of cast iron and the thickness of the body wall, special attention should be paid to it.

Cells can be roughly divided into boiling, bubbles, edge bubbles, wire mesh bubbles, welding bubbles, pinholes, bullet points, burst points, etc.

Boiling: When the cover coat is fired to about 600°C, the ground coat will sometimes boil, and the gas escaping at this time will destroy the cover coat and form black spots. Reboiling is related to scaling, which is caused by hydrogen bubbles. If the hydrogen pressure is insufficient, it does not escape during the first firing, and the second time it will reboil due to the expansion of hydrogen bubbles. If the ground coat is left for too long after firing, the re-boiling will be aggravated by applying the cover coat, so it must be fired first before glazing.

Bubble: The cause of bubbles is generally because the iron billet is not cleanly pretreated or pickled too much, the steel plate has too much hydrogen dissolved or contains too much carbon, sulfur, and phosphorus, the enamel is not melted, or the enamel slurry is mixed with impurities, and Insufficient firing of ground coat. It is also possible that the kiln contains excess water vapor causing hydrogen contamination.

Pinholes: Pinholes are prone to appear on the porcelain surface due to the high firing temperature or long time of the ground coat or cover coat. For the iron billet, it is necessary to pay attention to whether it is because there are many cementites in the cast iron, pinholes appear in the porcelain layer at the local white mouth of the casting, or the enamel of the cast iron has too much enriched sulfur.

The above is the analysis of the common problems and causes of foam cells. The production process of enamel is very complex and is completed by many processes. Once the enamel product is defective, it is difficult to directly find the cause because there are too many influencing factors, and different products have different quality. Different requirements, defects and standards cannot be generalized, and need to be analyzed on a case-by-case basis.

Scan the QR code to read on your phone

CONTACT US

Location:No199, North Zhujiang Road Tianyuan District,

Zhuzhou City, Hunan Province, China

Tel:+86-731-28212146 +86-731-28212147

Mobile: +86-13574208778

Email: jack@nolifrit.com

WhatsApp : +8613574208778

WeChat :+8613574208778