News

Cast Iron Enamel Defects And Their Influence On The Quality of Enamel Products

- Categories:Company news

- Author:

- Origin:

- Time of issue:2022-04-14

- Views:0

(Summary description)An enamel product has to go through hundreds of processes from the manufacture of the metal body to the melting of the enamel frit to the completion.

Cast Iron Enamel Defects And Their Influence On The Quality of Enamel Products

(Summary description)An enamel product has to go through hundreds of processes from the manufacture of the metal body to the melting of the enamel frit to the completion.

- Categories:Company news

- Author:

- Origin:

- Time of issue:2022-04-14

- Views:0

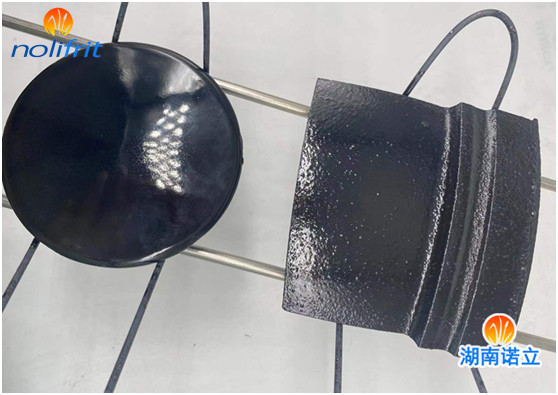

An enamel product has to go through hundreds of processes from the manufacture of the metal body to the melting of the enamel frit to the completion. Any mistake may cause defects in the enamel product, not to mention that the causes of many defects are very complicated. It's more difficult. The defects of enamel products can be divided into hundreds in detail, which can be simply classified as porcelain layer defects, iron billet defects and other defects. Today, we will briefly analyze the defects of enamel cast iron bodies and their impact on the quality of enamel products.

1. Stomata

Stoma is a kind of exposed or hidden blisters in the iron billet. Its surface is usually clean and smooth, but if the iron billet contains pores, it may cause the porcelain layer to fall off, the enamel product to boil or overburn, and sometimes the porcelain enamel surface will be damaged by gas. expansion leads to cracking.

2. Cellular

The reason for the honeycomb is that the local sulfur content is high, and the metal liquid fluidity is poor, resulting in the phenomenon of cold cast iron. The formation of honeycomb during casting will cause bubbles or air holes in the enamel layer.

3. Trachoma

"Tracho" is caused by the sand used for modeling staying in the casting body, and casting with chilled cast iron will also produce this defect. Trachoma is one of the causes of milling holes and cracks in the enamel layer.

4. Scum Eye

"Slag hole" is the slag inclusion that falls into the cast slag which is not cleanly removed during casting. The slag hole will cause milling holes, cracks and de-ceramic in the enamel layer.

5. Cold compartment

It is a type of crack where the edges are fused. When the chilled cast iron with low phosphorus content and high sulfur content is cast, it is easy to generate cold insulation. Generally, cold insulation is not easy to be found on the surface of the casting, but cracks or disjoints in the enamel layer will be found during firing.

6. Edge Crack

This defect generally occurs on the edge of the product and is caused by stress. Improper structure of the product will lead to uneven shrinkage of the enamel layer; excessive sulfur content in the iron billet increases the hot brittleness of the cast iron, and the iron billet falls off. If the film is too early, white mouths will appear in individual parts, and cracks and discoloration will occur in the enamel layer of this part.

7. Scar

It is caused by the small sand being covered by the cast iron film during casting, which will cause poor adhesion of the porcelain layer. The edge of this cast scar is often protruding above the porcelain layer.

8. White mouth

The existence of white mouth in the casting is detrimental to the quality, because it has different physical and mechanical properties from the casting itself, especially the thermal expansion coefficient. The product will crack or crack when fired.

9. Acute angle

It is the part where the two enamel surfaces are connected to form an acute angle. In this part, the ground coat and the cover coat are often either too thin or too thick. Overfire occurred due to the thin base coat layer, and many pores and air bubbles were built up. Cracks, wrinkles, etc. will be formed if the base and top coat layers of these parts are applied.

10. Uneven wall thickness

If the wall thickness is too different, the product will be heated unevenly during firing, some parts of the ground coat will be over-fired, and some ground coat will still be raw, and the product will be unevenly cooled, resulting in uneven color (matte), falling off or cracking of the enamel. . Generally, the thickness is not different from 1/2 as the standard, and it will not be easy to have good quality if it exceeds.

Scan the QR code to read on your phone

CONTACT US

Location:No199, North Zhujiang Road Tianyuan District,

Zhuzhou City, Hunan Province, China

Tel:+86-731-28212146 +86-731-28212147

Mobile: +86-13574208778

Email: jack@nolifrit.com

WhatsApp : +8613574208778

WeChat :+8613574208778