News

What Should I Do If Enamel Surface Is Boiling Or Grit Appears After Ground Coat Is Fired?

- Categories:Company news

- Author:

- Origin:

- Time of issue:2022-09-09

- Views:0

(Summary description)Enamel boiling refers to the accumulation of bubbles, pinholes, black spots, focal points, etc. on the surface of the cover coat layer due to excessive boiling of the

What Should I Do If Enamel Surface Is Boiling Or Grit Appears After Ground Coat Is Fired?

(Summary description)Enamel boiling refers to the accumulation of bubbles, pinholes, black spots, focal points, etc. on the surface of the cover coat layer due to excessive boiling of the

- Categories:Company news

- Author:

- Origin:

- Time of issue:2022-09-09

- Views:0

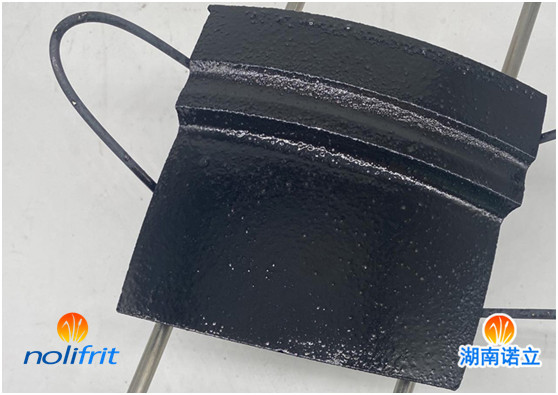

Enamel boiling refers to the accumulation of bubbles, pinholes, black spots, focal points, etc. on the surface of the cover coat layer due to excessive boiling of the ground coat layer during the firing of the ground coat, and the porcelain surface presents a boiling state of obvious loss of light. , usually caused by 5 reasons.

1. The ground coat is too thick and the temperature of the firing furnace is too high. The enamel should not be too thick, and the furnace temperature for firing needs to be adjusted and controlled;

2. Excessive amount of electrolyte added (for "electrolyte", please refer to the article "Application of Sodium Nitrite in Enamel");

3. The ground coat is not fully melted, and the ground coat should be fully melted;

4. Air leakage from the firing kiln, high humidity or reducing atmosphere. Enamel manufacturers need to overhaul the kiln in time to maintain an oxidizing atmosphere in the kiln;

5. Due to the temperature in summer, the temperature when grinding the ground coat is too high. When grinding the enamel slurry in summer, it can be cooled with water. To prevent boiling, potassium chlorate can be added to a small amount of general organic matter.

Particle defects on the enamel surface, as the name suggests, are rough particles that can be seen on the enamel surface after the ground coat is fired. You can refer to the following 3 reasons:

1. After grinding, if the sieving is not completely cleaned, or there are broken balls mixed in, the enamel slurry must be sieved strictly;

2. During the aging or storage process of the enamel slurry, garbage sand is mixed in, and the enamel slurry must be kept clean;

3. Enamel manufacturers need to overhaul the firing furnace due to slag loss from the firing kiln.

Scan the QR code to read on your phone

CONTACT US

Location:No199, North Zhujiang Road Tianyuan District,

Zhuzhou City, Hunan Province, China

Tel:+86-731-28212146 +86-731-28212147

Mobile: +86-13574208778

Email: jack@nolifrit.com

WhatsApp : +8613574208778

WeChat :+8613574208778